In view of the increasing demand from Zhengzhou automobile industry in recent years, Yizumi have been expanding its local market share of two-platen injection moulding machines, providing automotive functional decorative parts solutions for the auto maker suppliers.

In a factory located in the Zhengzhou Economic Development Zone, China, a Yizumi 1600T D1 two-platen injection machine was engaged in regular production, producing MG (Morris Garages) door panels with a cycle time of 50 seconds. It was the first time that Zhengzhou Bonaire Auto Spare Parts Co., Ltd. had purchased Yizumi equipment. The cooperation had boosted the confidence of the company in view of the future development in lightweight construction and integrated parts businesses.

According to the Bonaire General Manager Mr. Zhong Binde, he had years of experience in the production of auto spare parts in Wuhan and Shiyan. His research team had even joined with Dongfeng Nissan Company to develop a new modified material to replace the steel automobile rear door anti-collision frame. With market expansion, Mr. Zhong founded a new company with his team in Zhengzhou in 2016 to fulfil the parts manufacturing needs of his clients such as Dongfeng Nissan, SAIC Motor, etc.

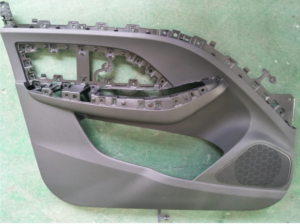

In a space of two years, the Bonaire’s business grew rapidly. It covers from a single product to a range of diversified products, including automotive interior parts, dashboards, integrated air-con ducts, door panels, etc. The annual production volume experienced an exponential growth. Nowadays, he had already clinched the orders of related parts from SAIC Motor MG ZS, a new generation of small SUV, a new generation of Sedan AP3X, and other car models. Among them, the production output from Yizumi 1600D1 two-platen machines was exactly the MG ZS door panel. The machine’s relatively high efficiency coupled with robust stability had ensured the fulfillment of stable production, achieving super-fast deliveries.

Talking about the future collaboration, Mr. Zhong expressed that he was very excited and interested to work with Yizumi in the new technology areas. “This year, the research team would shift to Zhengzhou in order to get further cooperation with the world-class suppliers and automotive factories. We intend to innovate the product technology and material development specific to the trends like new energy vehicles and weight reducing. Yizumi’s two-platen machine partnered with low-pressure injection moulding technology, FoamPro microcellular foam process and deco part moulding process would enable us to realize our ideas soon.”

According to reliable sources, the production of new energy cars in Zhengzhou started in 2015, and the annual production output in 2017 was 31,000, an increase of 17.1% over the same period. The growth rate of 26.4% was faster than that of the total car production volume. It occupied 6.6 percent of the total car production volume. The consecutive investment of new energy car projects in Zhengzhou by companies such as SAIC Motor, Yutong, etc. has even increased the confidence of the auto spare parts industry. Zooming in to the development prospects of new energy cars, Yizumi will expand the service to the whole Henan Province, delivering upgrading and renewal solutions of the decorative, functional parts for the local automotive industry.

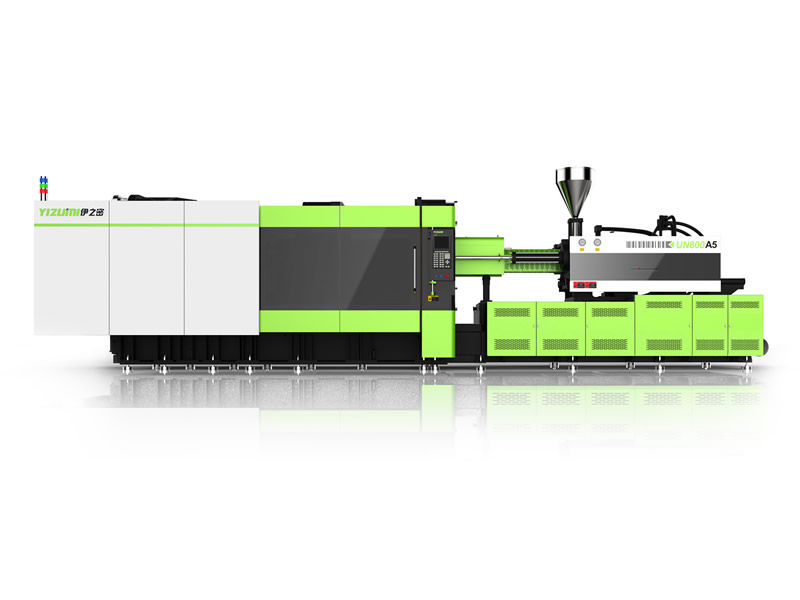

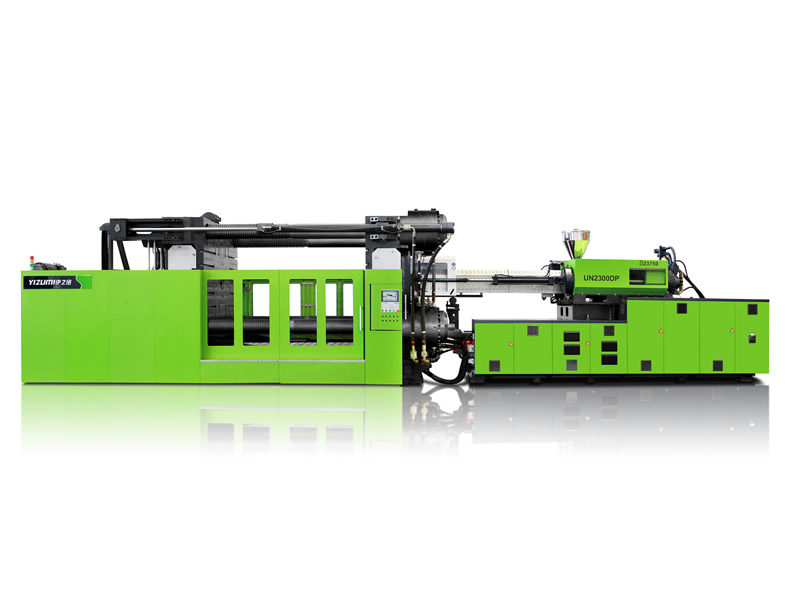

Yizumi DP series two-platen injection moulding machine

MG Car

Interior trim part

Interior trim part