A5 Standard Series High-end Servo Injection Molding Machine

This machine is newly upgraded from the A5 range enabling a wide range of products for engineering components. It is fast and efficient using an upgraded screw and barrel assembly with fast plasticising and quick response. Ideal for caps, jars, containers, fittings and engineering products.

New A5,Excellent As Always

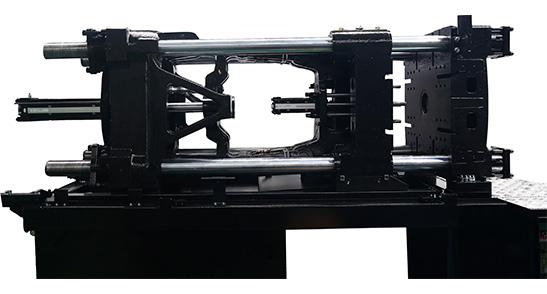

Clamping unit

Highly solid, reliable and durable

Platens of the machines in A5 series are highly-rigid so that the rigidity of the clamping unit is up by 30%. The uniform stress molding technology and high-rigidity T-slot platen design can protect the platens and molds and increase the lifespan of platens. Special anti-tilt platen support design and low pressure mold protection can effectively protect the mold. Forced ejector reset enables the molds to be more applicable.

Injection unit

Precise and stable with superior effect of plasticizing

Optimized design of injection unit increases the rigidity, ensures coaxiality of the forces on motion and injection and reduces the resistance. High-efficiency mixing screw is standard on the whole series of machine, considerably increasing the plasticizing efficiency and quality and achieving outstanding color mixing effect.

Hydraulic system

Energy saving, high efficiency and low noise

In regards to the optimization of the servo system, it redefines more superior configuration. Assembled with renowned specialized motor, imported high-pressure gear pump and Inovance servo driving device, the third generation servo system can realize low noise, strong power and fast response.

Human-machine Interface Meeting High Requirements

The split screen technology makes the display clear and concise. Relying on the marking of various procedures, it can easily accommodate new process or delete process, and check the authenticity of the process.

Easy to Operate

The user-friendly design has covered the operational requirements, allowing the users to get started with the system quickly.

Strong Functions

With storage of 120 sets of common process programs, the users can use them according to their needs, meeting different injection molding requirements.

Wide Scope of Application

With larger specifications and parameters, stronger power engine and much faster response speed, the end-users can achieve a broader scope of processing, substantially lowering the recurring investment costs.

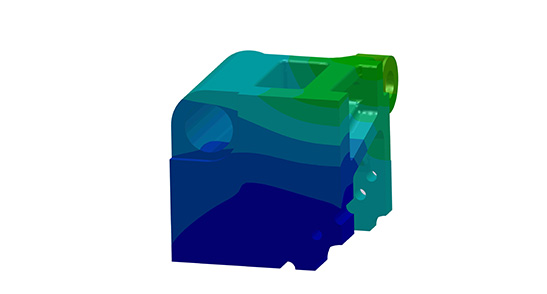

Highly Precise and Stable

The comprehensive structure optimization of the injection machine ensures the precision and stability.

Human-centered

The user-friendly interface between human and machine, and the integration of large volume of commonly used function-related software make handy execution of operability and maintainability, offering the end-users more freedom and comfort in their operation.

Reliable and Durable

The whole machine is integrated with reinforced strength. It uses uniform stress compression molding technology, resulting in a more stable machine operation. In addition to its superior reliability, it is also very durable.

High Efficiency and Energy-Saving

Embedded with the third generation of servo system, the whole machine operation has very low noise production, while its engine is strong and its response is also very speedy.